-

Specialty Material Engineering

Providing a one-stop solution for all your Value added Materials requirement.

Specialty Material Engineering

Providing a one-stop solution for all your Value added Materials requirement.

Specialty Material Engineering

Providing a one-stop solution for all your Value added Materials requirement.

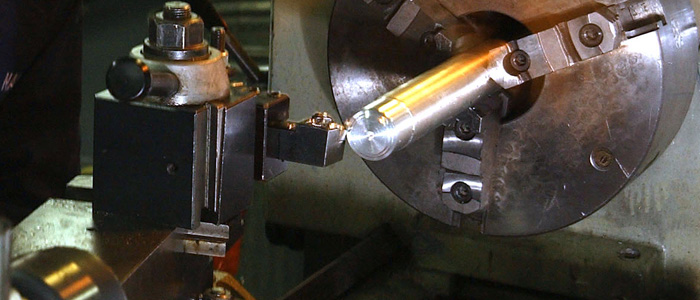

Specialized Processes

Dies/Tools Designing & Manufacturing. Sub-assemblies & assemblies. Semi-finished & finished components.

Core Strengths

Technical Expertise. Specialist Support & Certification. Quality. Customer Focused. Commitment.

Customer Advantages

Wide Range of Products. Value-Addition. Application Knowledge. End-to-End Solutions Provider.

About Val-Met

Val-Met is a Niche-Oriented End-End Solutions Provider in the field of High Performance Materials & Components.

“Val-Met” signifies Value-Added Materials

Business Offerings

- Supply Chain Management of High-Performance Materials.

- Manufacturing & Supply of Value-Added Cut Parts, Near-Net Shapes, Components & Sub-Assemblies.

High-Performance Materials

- Nickel & Cobalt based Super Alloys

- Alloys of Titanium, Zirconium & Niobium

- High Strength Aluminium Alloys

- Specialty Steels & SS

- Austenitic & High Austenitic grades of Stainless Steel.

- Precipitation Hardened grades of Stainless Steel.

- Martensitic grades of Stainless Steel.

- Double & Triple Melted Steels & Stainless Steel.

- Duplex and Super-duplex grades of Stainless steel.

- Maraging Steel

Forms

- Long Products – Bars & Billets

- Round, Rectangle, Square & Hexagon.

- Ingots

- Round, RCS, AS-Forged

- Flat Products – Plates, Sheets, Strips & Coils.

- Wires – Welding Wires & Cold-Heading Quality Wires

- Extrusions

- Tubes & Pipes – Seamless, Welded, Welded & Drawn

- Hollow Bars

- Forgings & Castings

Value-Added Parts

In-House Capabilities

- Water-Jet Cutting

- Cut-to-Size

- Sheet & Plate Grinding

- 3-Axis Milling

- Turning

- Horizontal

- Sliding Head

- Conventional

- Peeling

Additional Capabilities

- Vertical Turning

- Wire-Cut & EDM

- 4 & 5-Axis Milling & Turning

- Slitting & Shearing

- Laser Cutting

PROCESSES & SERVICES

HIGH PERFORMANCE MATERIALS

Supplies to demanding applications. Difficult-to-find/Difficult-to-source materials.

Know more

HIGHLY ENGINEERED COMPONENTS

Concentrate on Components of specialized materials. Undertakes single point responsibility.

Know more

TECHNICAL CENTRE

Val-Met Engineering is built on the highest level of technical understanding and knowledge.

Know more

TESTING & CERTIFICATION

We have the capability to carry out Material testing to meet & qualify to all standards of requirements.

Know more

DESTRUCTIVE TESTING

Mechanical Testing. Chemical Analysis. Metallographic Test.

Know more

NON DESTRUCTIVE TESTING

ASNT qualified Ultrasonic Test. Acceptance: Class AA, Class A. Liquid Dye Penetrate Test.

Know moreA one stop solution for all Material requirement for various industries.

We provide innovative solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market.

Business Areas

At Val-Met, we are constantly meeting up with customers standards and are focused on delivering the products to satisfy the customer demands. We provide raw materials for customers from different fields of aviation and defence.